OLED panels are classified into three different displays; monochrome, multi-color and full-color, of which full-color production requires the most complicated technology. In terms of driver electronics, OLED is also categorized into PMOLED and AMOLED. (Note, OLED and LED are two distinct products.)

Advantages of OLED include:

-Self-luminescent properties

-Wide viewing angle

-High contrast

-Low power consumption

-Rapid response

-Full color

-Simple manufacturing/production.

In terms of production, we supply most OLED deposition materials:

-Organic materials

-Metal materials

-Materials for sealing glass

-Consumables: e.g. -crystal sensors, fine metal and deposition open masks, and

Polyimide (PI) coating equipment.

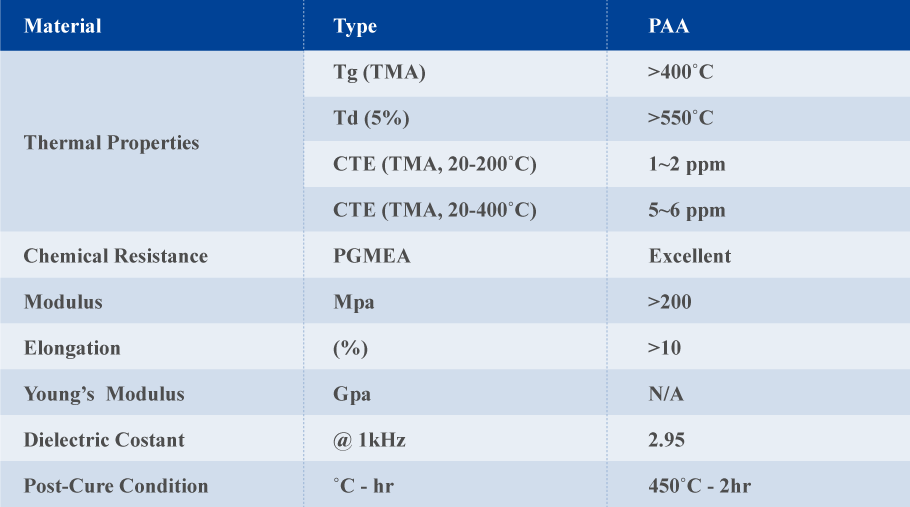

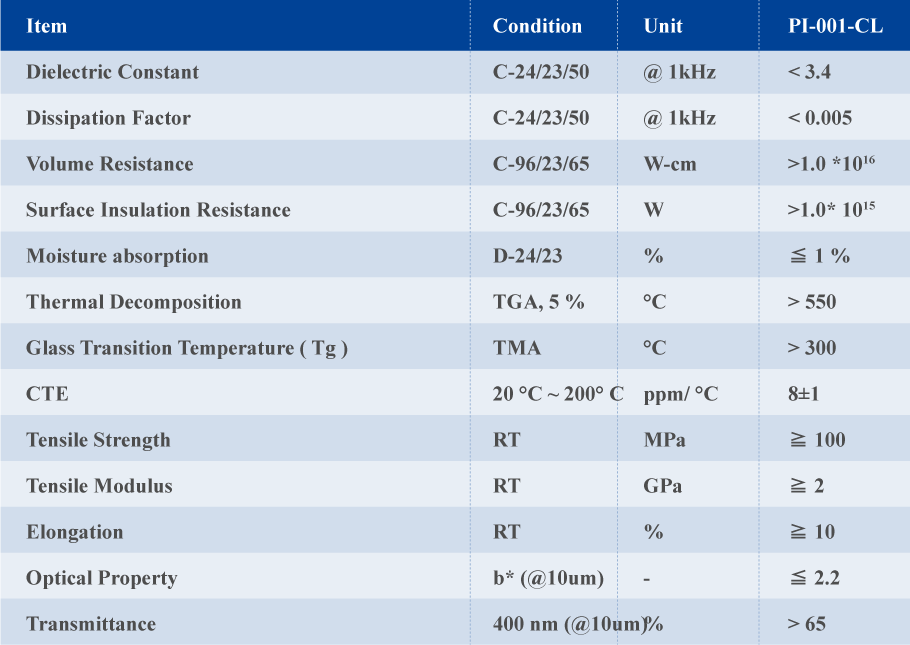

Polyimide is the key material in Flexible Displays and stands above many other high polymer materials. As a perfect substrate for flexible OLED displays, polyimide’s high heat resistance and chemical properties –combined with high transparency, makes transparent PI a very favorable material for high-end TP (Touch Panel) sensors.

Cholesteric reflective polarizer films (CRP), in conjunction with quarter wave films (QWF), are used in LCD displays to enhance the brightness of cell phone, NB, and TV screens while lowering power consumption. In lieu of traditional iodine dye, dichroic dye is used on the polarizer in a CRP for items such as car dashboards, aircraft, and liquid crystal projectors, demanding high heat resistance and endurance. In addition to weather resistance, dichroic dye has a birefringence optical property that none of the other dyes have.

Beryl Chang

【TEL】

02-2719-3126 Ext. 1841

【EMAIL】

Beryl@gredmann.com

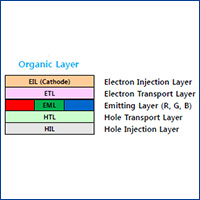

►OLED Organic Material

OLED organic materials are categorized based on different functions : electronic transmission layer(ET), electron injection layer (EI), hole transmission layer (HT), hole injection layer (HI), red-blue-green host-emitting layer(RD/RH、BD/BH、GD/GH), dopant and so on.

Advantages:

1. Microsecond reaction time ~1μs

2. Paper-thin panel (2mm)

Applications:

The organic thin-film transistor integration can convert energy into visible lights. With various organic materials, it radiates different lights so as to meet the requirements for a full-color display.

►Flexible Substate Polyimide Material

Transparent and high temperature PI’s play a significant role in flexible displays and are some of the best insulation materials in the world.

Advantage:

-Slim but durable

-High temperature resistance

Used on OLED deposition equipment and related consumables. -e.g. Crystal sensors, shadow masks, metal materials, etc.

About OLED deposition related consumables and equipment:

Consumables:

-Crystal sensor: Frequency: 5MHz and 6MHz. Suitable for most deposition controllers/monitors on the market.

-Deposition shadow mask (FMM & CMM): For the manufacturing of OLED display glass substrate during the process of depositing organic materials for organic film production, and are also used for the deposition of the electroluminescent material onto the substrate of the OLED display.

-Inorganic material deposition (metal material): For OLED electrodeposition, used on lithium wire, lithium fluoride crystal, magnesium crystal, silver crystal, aluminum crystal, etc.

Equipment:

-Packaging equipment (PECVD)

-Flexible PI laser removal equipment

Yellow Light In-Line Equipment, Strong Adhesive PI Coating Equipment

Yellow light manufacturing devices, flexible substrate adhesive PI coaters, and muffle furnaces which are applied to LCD and touch panels.

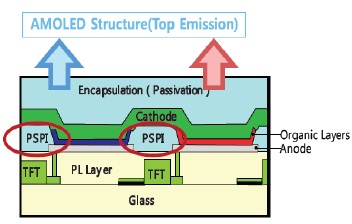

| ► | OLED Organic Photoresist Insulation Layer |

The material is used to separate phosphors (fluorescent materials) and to provide insulation during the OLED process

Advantages:

-High transparency (90% light transmittance)

-High Remained Film Thickness Rate, R.F.T.R. (more than 70%)

Applications:

-LTPS TFT process

-AMOLED panel process

-Flexible display

►Anisotropic Conductive Film (ACF)

Synthesized from high-quality resin and conducting particles, mainly used on connecting two different base materials and circuits, which need conductivity. ACF is moisture-proof, adhesive, conductive, and insulating.

Advantages:

-Powerful adhesive

-Low “on-state” resistance

-Highly durable

-Flexible

Applications:

-Flexible flat cable

-Flex On Glass (FOG), flexible, thin, and printable,

used in the circuit/glass lamination manufacturing

process