Display used conductive films and low-retardation films, anti-reflection and anti-fingerprint high transparency thin films and EMI shielding metal mesh film. Conductive films can also be applied as electro luminescent, LCD heater, smart window, E-paper, . Production line used laser equipment and lithology equipment.

Focusing on industrial market touch panel integrated solutions in military, medical, gaming, industrial computers, avionics, Kiosk, POS, digital signage industries, able to provide customized resistive and capacitive touch panels with LCD direct bonding service and air bonding service according to customer needs.

Resistive touch panels includes 4 wire, 4 wire multi-touches, 5 wire, 5 wire multi-touches, and 8 wires;Projected Capacitive touch panels uses traditional ITO glass, as new material Metal Mesh specifically provides low resistance enabling large size support, enriching projected capacitive touch panel size range from 3.5" to 70".

Metal Mesh can function as EMC shielding, meeting Military Standard 461F and applied in military and medical used EMI shielding glass and EMI protection boards. Outdoor touch panels can provide anti-glare, anti-reflection, sunlight readable functions, LCD heating and explosion proof functions. Supplying all kinds of metal and non-metal powder, applying in powder metallurgy, brake lining, pneumatic and hydraulic noise insulators, welding and refractory industries.

Andy Liu

【TEL】

02-2719-3456 Ext. 2181

【EMAIL】

Andy@gredmann.com

►Conductive Film OC Series

CPFilms produces a wide line of optically clear indium/tin oxide (ITO) coated transparent, conductive film products. OC products have many uses, for example, as components of touch screens and other position sensors, electroluminescent (EL) lamps, liquid crystal devices, electrophoretic displays, smart windows and transparent heaters.

【Downloads:Conductive Film OC Series】

►OCA

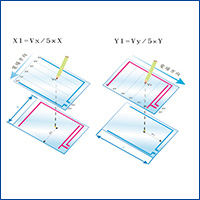

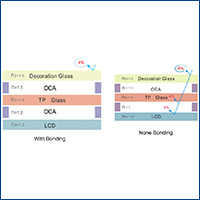

Applying in LCD bonding:

Due to the different reflection rate of glass and air, when light passes through the middle layer, it would refract and scatter, limiting light transparancy. Choosing OCA as the adhesive and apply in the middle, to reduce light refraction, and therefore having a higher transparancy.

Features:

1. High adhesive force, high transparency over 90%

2. When being applied between glass and PC, it also provides high transparancy

3. Multiple thickness range(50-200um)

►Decoration Film Anti-Scratch PET

Japan KIMOTO KB series HARD COAT PET FILM ,applying on all Displays or Resistive& Projected Capacitive Touch Panel Decoration Film

【Downloads:PET1】

【Downloads:PET2】

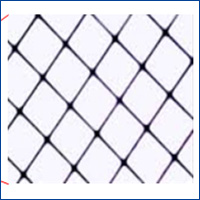

►Metal Mesh

Metal Mesh features:

Metal Mesh Projected Capacitive Touch Panel provides low resistance,serving as the perfect material for large-sized touch panels

Metal Mesh Film functions EMC control, fitting particular needs in Medical and Military special EMC Shielding requirement.

Metal Mesh film standard size 500*600mm with/without adhesive or customized sizes.

【Downloads:Metal Mesh (Without OCA)】

【Downloads:Metal Mesh (With OCA)】

【Downloads:Metal Mesh (ENG)】

►Resistive Touch Panel

Providing all kinds of multi-touch, single touch resistive touch panel customized service. For Automotive industry, main application is 5 wire multi-touch Resistive touch panel with 3 touches sensor available. Resistive touch panel has great stability, suitable for POS and Automotive.

【Downloads:Resistive Touch Panel】

►Projected Capacitive Touch Panel

Providing 10 points touch customized service. Projected capacitive touch panel uses PCB equipment on lithiology process etching thin lines, line space/width can be as thin as 30/30um, ideal for thin border requirement.

【Downloads:Projected Capacitive Touch Panel】

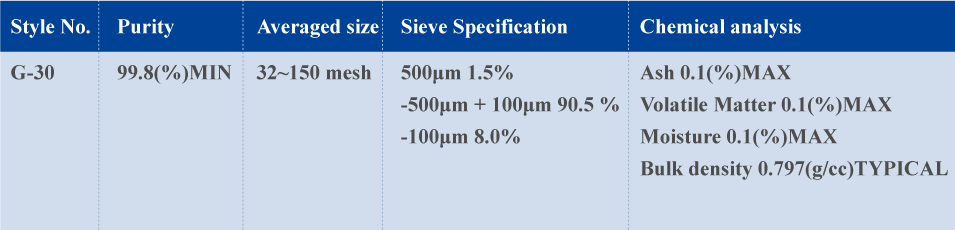

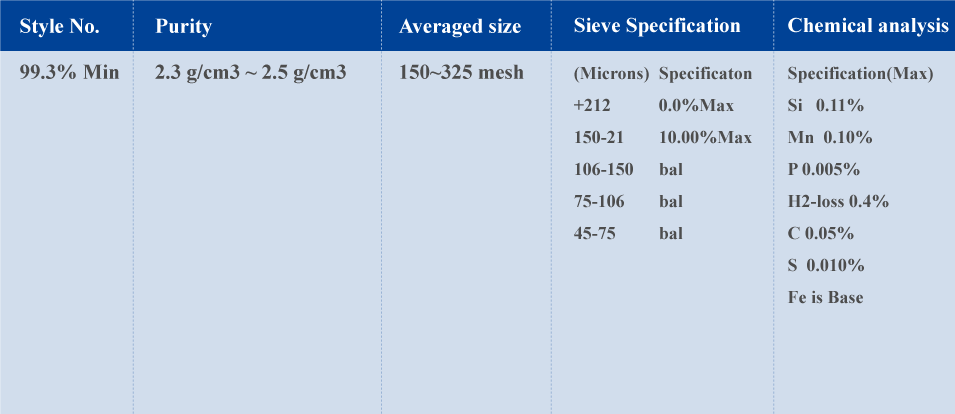

►Graphite

Graphite powder has diverse application, and it features of abrasion resistant, conductivity, heat conducting and lubricity, etc.. It can apply to fireproofing materials, conducting materials and frictional materials.

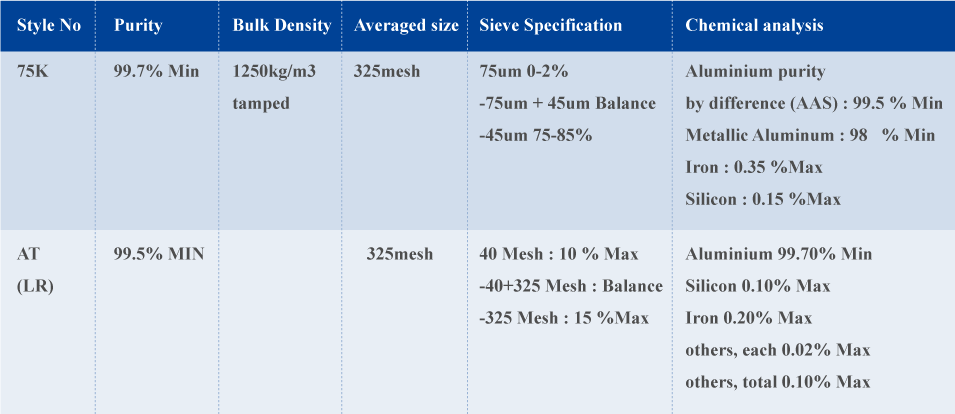

►Aluminum Powder

Aluminum is one of commonly used industrial metal, with excellent properties in terms of conductivity, heat conducting and thermal conductivity, and thermal stability, can be used infireproofing materials, conducting materials and frictional materials.

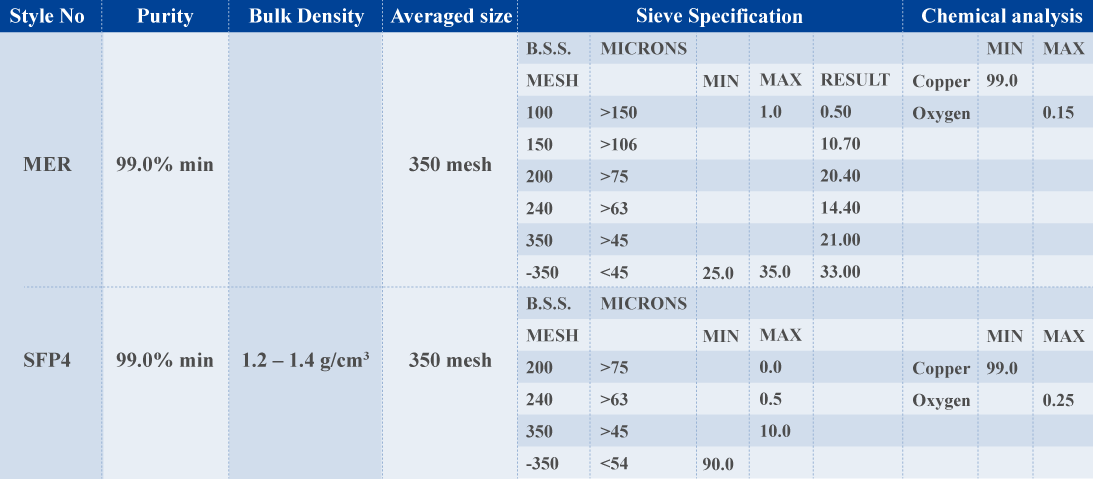

►Copper Powder

Copper powder has property of excellent conductivity and heat conducting, also with more competitive price than iron. It can apply to industry of powder metallurgy, oil-impregnated bearing, braking lining, etc..

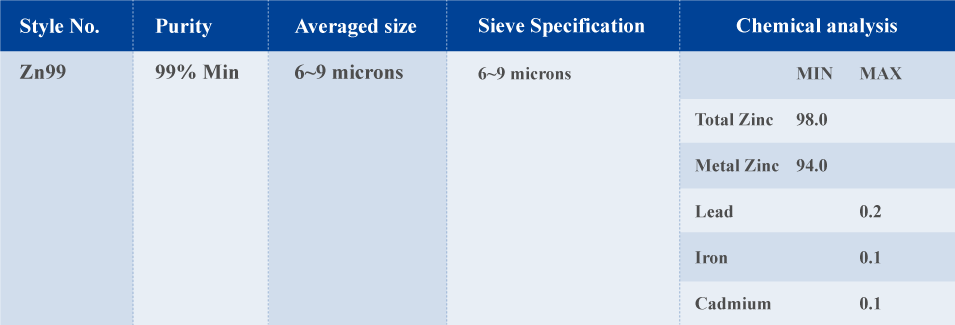

►Zinc Powder

Zinc is used for combustion, explosion, welding, and features of thermal stability, permeability, adhesion, and reduces friction as well.

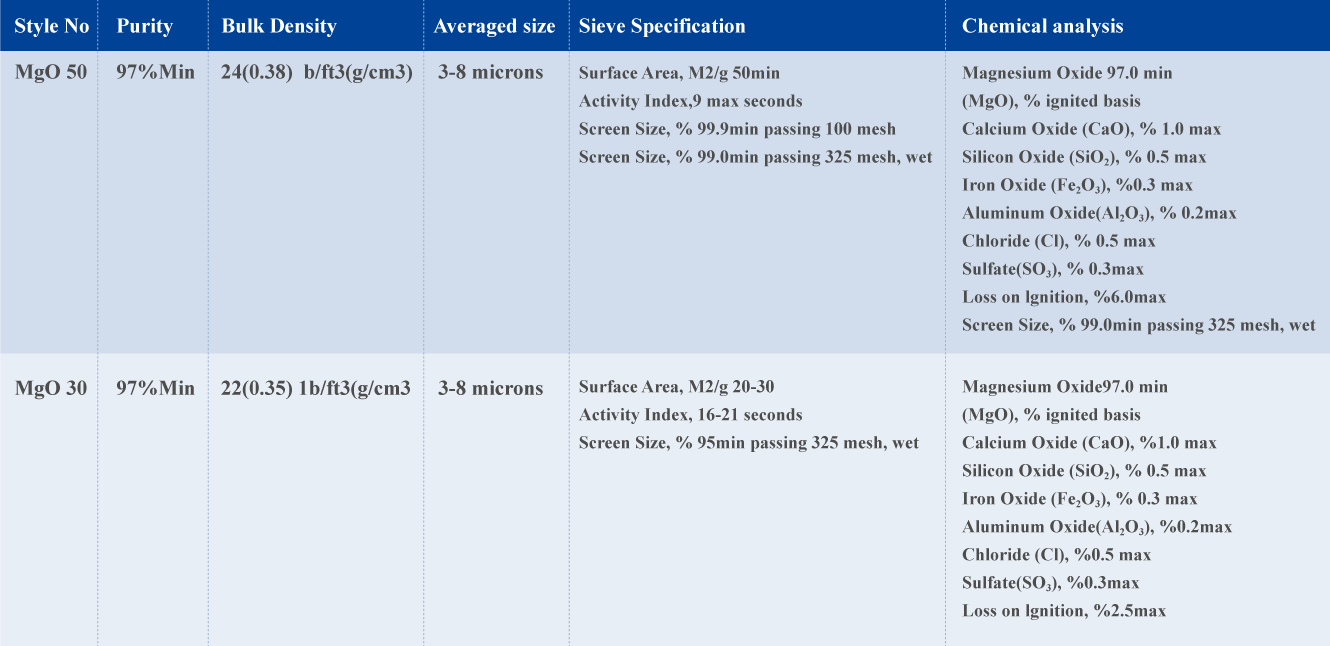

►MagChem

MgO can be used in fire resisting material and brakelining, etc., with properties of fire resistance and insulation in high degree.