►Flat-panel Display Material Div

We provide competitive used equipment and turn-key solution to reduce customer’s investment and lead time, and continuously introduce the state of the art equipment in flat-panel display field.

(1) Field:

TFT, CF, TP & Module

(2) Plate size:

100mm & 200mm square for Laboratory line, G2.5~G4.5 for mass production line

(3) Used equipment list for FPD:

(1) TFT –Array including CVD, PVD, Coater, Stepper, Exposure, Develop, Etch,

Stripper, etc.

(2) LTPS-Array including ELA, Ion implanter, Activation & Hydrogenation, etc.

(3) TFT-CELL including PI, Rubbing, ODF, etc.

(4) Color filter including Coater, Exposure, Develop, in-line sputter, etc.

(5) Touch panel including 5”~G6 Glass type TOL, OGS, GG, photo & sputter; width

more than 500mm Film type Roll to Roll photo & sputter.

(6) Other process: Glass tempering, Glass Slimming, edge seaming equipment

etc.

(4) Used equipment list for solar:

Solar Cell: Texture, diffusion, printer, isolation, implant, etc.

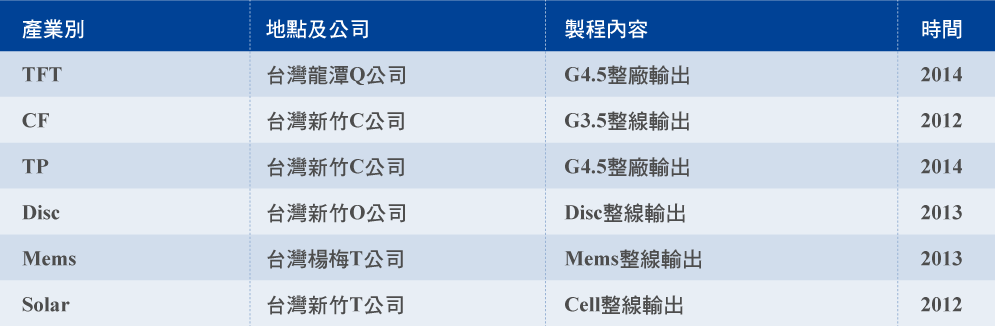

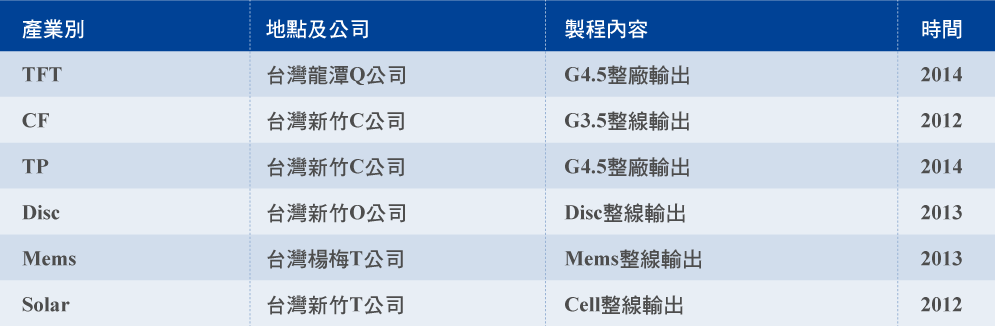

(5) Package plant export reference:

(6) Business scope:

【From used equipment to turn-key solution】

(1) Used equipment trading:

Providing equipment for TFT, LTPS, AMOLED, PMOLED, TP and upper,

middle & lower stream of solar industry.

(2) Dismantle, transportation & reinstallation:

Recoverable dismantle, international standard packing & transportation,

reinstall & fine tune in customer site.

(3) China import license for used equipment:

Assist in applying CCIC certification.

(4) Technology transfer:

Providing process technology transfer.

(5) Parts trading:

Trading used equipment parts.

(7) Brand-new equipment:

【IJP(INK Jet Printer)】

IJP is well substituted for traditional printer, well performance in fine pitch coating and suitable for 2.5D glass, also suitable for PR & pattern on flexible substrate. It’s new trend for printer.

【Array Test-TEG】

Array test device for display panel, contact type measurement, high measurement accuracy and precision, suitable for each brand of probers, better accuracy and precision than optional type.

【Blade Type Edge coating machine】

Slim & blade type edge are the requirements for high-end phone, reinforced glue coating for module gap less than 100um, reducing material and lamination cost, total strength reach at least 15 N. With higher efficiency and accuracy comparing to other printer.

(1) Field:

TFT, CF, TP & Module

(2) Plate size:

100mm & 200mm square for Laboratory line, G2.5~G4.5 for mass production line

(3) Used equipment list for FPD:

(1) TFT –Array including CVD, PVD, Coater, Stepper, Exposure, Develop, Etch,

Stripper, etc.

(2) LTPS-Array including ELA, Ion implanter, Activation & Hydrogenation, etc.

(3) TFT-CELL including PI, Rubbing, ODF, etc.

(4) Color filter including Coater, Exposure, Develop, in-line sputter, etc.

(5) Touch panel including 5”~G6 Glass type TOL, OGS, GG, photo & sputter; width

more than 500mm Film type Roll to Roll photo & sputter.

(6) Other process: Glass tempering, Glass Slimming, edge seaming equipment

etc.

(4) Used equipment list for solar:

Solar Cell: Texture, diffusion, printer, isolation, implant, etc.

(5) Package plant export reference:

(6) Business scope:

【From used equipment to turn-key solution】

(1) Used equipment trading:

Providing equipment for TFT, LTPS, AMOLED, PMOLED, TP and upper,

middle & lower stream of solar industry.

(2) Dismantle, transportation & reinstallation:

Recoverable dismantle, international standard packing & transportation,

reinstall & fine tune in customer site.

(3) China import license for used equipment:

Assist in applying CCIC certification.

(4) Technology transfer:

Providing process technology transfer.

(5) Parts trading:

Trading used equipment parts.

(7) Brand-new equipment:

【IJP(INK Jet Printer)】

IJP is well substituted for traditional printer, well performance in fine pitch coating and suitable for 2.5D glass, also suitable for PR & pattern on flexible substrate. It’s new trend for printer.

【Array Test-TEG】

Array test device for display panel, contact type measurement, high measurement accuracy and precision, suitable for each brand of probers, better accuracy and precision than optional type.

【Blade Type Edge coating machine】

Slim & blade type edge are the requirements for high-end phone, reinforced glue coating for module gap less than 100um, reducing material and lamination cost, total strength reach at least 15 N. With higher efficiency and accuracy comparing to other printer.

Victor Ho

【TEL】

02-2719-3126 Ext. 2302

【EMAIL】

Victor@gredmann.com

►Panel & touch display exposure line

Laboratory & mass production equipment for display field

• Alignment accuracy :

1.5um~5um for TFT ,7um for CF, 10um for TP

• Maximum plate size:

100mm & 200mm square for Laboratory line

G2.5~G4.5 for mass production line

►Inline sputter for display

• Inline sputter for display glass

• Maximum plate size:G2.5~G6

• Targets:ITO, Metal, Sio2, etc.

►PECVD for solar cell

PECVD for solar cell

• Brand:Centrotherm, R&R, OTB, etc..

• Wafer size : 6"

• Operated quartz tubes : 3~4 rubes

• Plasma source:4~8

• Throughput:1500~2400pcs/hr