There are 3 divisions in VAC - Permanent Magnets & Systems , Materials & Parts, and Cores & Inductive Components:

1. Permanent Magnets & Systems:Since 1973, VAC has been producing sintered rare-earth permanent magnets from SmCo and NdFeB. VAC is the magnet market leader in Europe for motor, automotive, train, wind-generator application.

2. Materials & Parts:In the Materials and Parts Division, VAC manufactures high-quality crystalline, amorphous, and nano-crystalline materials. All VAC alloys are melted in this division; including: soft magnetic materials, permanent magnets, magnetic semi-hard materials, and alloys with special non-magnetic properties. These materials are the basis for the product diversity of VAC. Recently, VAC has developed new material – materials for current sensor , CoFe alloy for linear motors, NiFe alloy for connectors to replace BeCu alloy , and brazing foil for heat-exchange soldering .

3. Cores & Inductive Components:

-Key parts for the Power Supply and Telecommunication Magnetic Core :

●The unique combination of high permeability with very low losses of the alloys is

the basis of the innovative VAC core range.

●The high-quality crystalline NiFe cores made of ULTRAPERM® have been

market leaders for decades. Optimization for technical and economic aspects

are constant to ensure the reliability of residual-current safety switches.

-Application : Cores for Magnetic Amplifier (MagAmp), EMI common mode

choke, core for power transformer, spike killer, etc.

●Components : Material knowledge is only one of many skills needed for the

inductive components and modules. VAC offers a low-cost design in an

optimized volume with maximum reliability.

-Application :

●Industry – current sensors, current transformers for electronic

watt-hour meters, drive transformer, etc.

●Telecom - Power Line Communication (PLC) transformer.

Apple Wu

【TEL】

02-2719-3456 Ext. 2211

【EMAIL】

Apple@gredmann.com

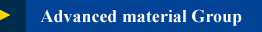

►Vitrovac 6025 Z - Amorphous Cores & Vitroperm 500 Z - Nanocrystalline Cores for Magamps

Magnetic Amplifiers (MagAmps) made of amorphous and nanocrystalline tape-wound cores are well-established worldwide for precise output voltage regulation in PC and server-switched mode power supplies, as well as telecom and industrial power supplies.

VITROVAC 6025 Z and nano-crystalline VITROPERM 500 Z feature a highly square hysteresis loop, lowest coercivity and losses. VITROPERM can function at a higher limit temperature up to 120°C.

►Vitroperm 500F - Nanocrystalline Tape-wound Cores for Common-mode Chokes - Plastic Case and Epoxy-coated Cores

Common Mode Chokes with toroidal tape wound cores of VITROPERM allow the effective attenuation of asymmetrical and conducted high frequency noise. The high permeability of the nanocrystalline core material achieves superior characteristics at low and middle frequencies, as well as in the high frequency range, when an optimized winding arrangement is chosen. In comparison to conventional ferrite, advantages over the entire frequency range are obtained.

The advantage of VAC VP 500F Common-Mode Choke

●High permeability , high inductance

●Smaller size than MnZn CMC

●Single Stage for EMI Solution

●Stable performance during different temperature

●VP 500F CMC is good for EMI Conduction and Radiation

●Reasonable price

●Fewer turns and less copper wire to save the cost

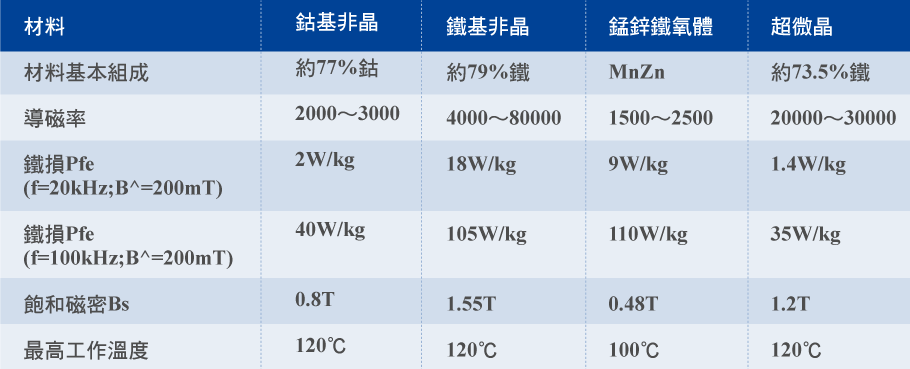

►Cores for Power Transformer

The supply of electrical devices and equipment in the industrial range today has almost exclusively changed to switched-mode power supplies, supplying one or more DC output voltages.

Different converter principles are in use depending upon the power range. Common converters include:

• Flyback converters (approx. 500W)

• Single-ended forward transformer (to

approx. 1000W)

• Push-pull converters (up to the KW

range).

In particular, toroidal tape-wound cores made of the VITROPERM nano-crystalline material are recommended for push-pull converters. Advantages over ferrites are achieved by the substantially higher induction swing (high Bs) in conjunction with low hysteresis loss: lower weight, smaller volume, higher efficiency, and an extended temperature range (up to 120 °C) with a negative coefficient. The larger the transferred power is, the more pronounced the advantages.

►Current Sensors

VAC current sensors for the isolated measurement of high frequency currents of arbitrary waveforms including DC are in use from the smallest up to the highest power applications in industry:

• Three-phase drives, servo drives, generators

• Power converters for DC - drives

• Battery-operated applications

• Uninterruptable power supplies

• Switched-mode power supplies

• Welding inverters

As the only manufacturer worldwide, VAC offers high accuracy current sensors which use a soft-magnetic probe instead of the hall generator as the magnetic field detector in a compensation-type sensor.

In comparison with conventional sensors, our products offer some principle-related advantages:

• Very small offset current with negligibly long-term

drift

• Practically no temperature-dependent offset

• Very small hysteresis of the offset current - high

resolution at low currents

• High usable temperature range (e.g. up to 110 °C

in an IGBT module)

• The magnetic module can be separated from the

electronics for applicational flexibility

• No electronics adjustment necessary

• Attractively prized

The electronics presented are intended for the operation with VAC passive current sensors. Depending on the type of electronics, one, two, or three sensor modules can be connected.

►Current Transformers for Electronic Watt-Hour Meters

Electronic watt-hour meters have gradually been replacing the electro-mechanical Ferraris–meters in industry for some years. Because of their many advantages such as extended scope of functions with system capabilities, insusceptibility to mechanical wear, small size and higher accuracy, they are also increasingly spread in private households all over the world. Their area of application covers a wide range from local individual devices through pre-payment meters right up to (supra)regional networked remote control and readout systems.

One of the key components in multi-phase and partly also in single-phase meters is the current transducer. This provides the electrical network isolation and supplies anaccurate measuring variable (signal voltage) for the primary current. With respect to its measuring error, it must meet the requirements defined in the various technical standards for the respective device accuracy class. In Europe these are usually the standards IEC 61036 for directly connected meters and IEC 687 for indirectly connected meters; for the Anglo-American market the standards of the ANSIC12.xx series for both types of connections.

There is a number of principles for implementation of the current transducer of which the toroidal core current transformer with low burden resistor has several obvious advantages

• closed magnetic circuit:less sensitive to interference fields usually no shielding required

• magnetic function principle without semiconductors: high long-term stability low need for additional circuitry

• simple assembly with just a few parts:low assembly expenses, compact designs attractive prices

Above contents are reference of Vacuumschmelze official document.

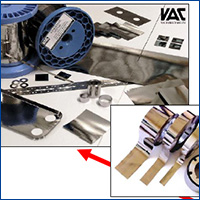

►Braze Foil - Vitrobraze Nickel-based Filler metals

In considering of the 5000 years of brazing history, the nickel-based filler metals are a very young group of materials. The first Nickel-BFM (brazing filler metals) was developed for joining parts of aero jet engines in 1947. This new group of BFM's and the brazing procedures therefore were in the following decades permanently improved. Modern alloys of this BFM group are optimized in corrosion resistance and bonding strength.

Our amorphous VITROBRAZE® filler metal foils will be produced by using the Rapid Solidification Technology, which is also used for our soft magnetic VITROVAC® and VITROPERM® products. The production of amorphous metals requires a manufacturing technology that operates on the basis of the necessary cooling rates, which is known as rapid solidification. Amorphous structures are characterized by the absence of a crystal lattice or a long range order. With this random, spatially uniform arrangement of the constituent atoms, their structure is similar to that of liquids.

The nature of this production process is the reason why amorphous alloys are offered only in the form of thin, ductile metal foils. Subsequently, tapes, parts and premorms can be made by e.g. slitting, cutting, stamping and etching.

Above contents are reference of Vacuumschmelze official website contents.

►Spring Alloy - Duracon 17A

DURACON 17A® is an Iron-Nickel-Cobalt (FeNiCo) alloy, which is characterized by high stability and high conductivity. These properties are established by high cold deformation and the deformation martensite that is present.

Typical Applications: DURACON 17A is suitable for switches, relays and plugs where high stability with high conductivity is required. After hardening, it is also suitable for thermo-switches.

Above contents are reference of Vacuumschmelze official website contents..